Week 1

Here is a summary of what we hope to accomplish our first meeting:

- Meet and greet

- Summary of the build

- Q&A about materials, timing, etc

- Certifications for new people on table saw/drill press/band saw

- Partnering up for now

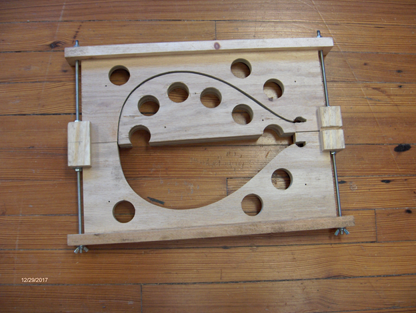

- Mould (jig) build-should look like this when done

- Any extra time-making sanding jigs for top/bottom radius

- Clean-up

Materials needed for this jig

–2 pieces of 3/4 plywood 6″ by 15″

–2 pieces of 1 x 4 18″ long

–some 1 1/4 screws to put it together

–a piece of 2 x 4 about 8 ” long

–2 all threads 16″ long

–4 screws for the all thread (wing nuts best)

–a piece of 2 x 4 about 18” long (radius sanding jig)

Week 2

Friday we’ll work on a couple different things to minimize bottlenecks at tools. I propose you break up into groups of 2 and work together on the same task. Here’s what we’ll work on and what you will need.

Sides – we’ll cut and dimension the 2 side pieces to 2” tall x .085” thick x 18” long.

Bend the sides to shape using a heated pipe.

Bring a heat gun if you have one. We’ll have a few so not to worry if you don’t have one.

Bring a spray bottle for wetting the sides while bending

Bring (2) 2” wide x 20” long strips of aluminum to aid in bending the sides if you have anything available. I have several made from scraps of gutter that we can use so don’t go out and buy anything.

Top and back – we’ll join the top pieces and back pieces. Final dimension 11” wide x 15” long

Neck – we’ll use either a solid block or glue a sandwich of 3 pieces for a neck with final dimension of 16” long x 2” wide x2.5” tall

Material needed:

Back and sides to match – I suggest one of the following: Mahogany, Walnut, Maple, Cherry

Top – Spruce (we have enough spruce from an old piano soundboard that you are welcomed to use)

Neck – We should have enough mahogany if you want to use it otherwise I suggest maple